Why do you need an automated inspection system for the production of PCBs?

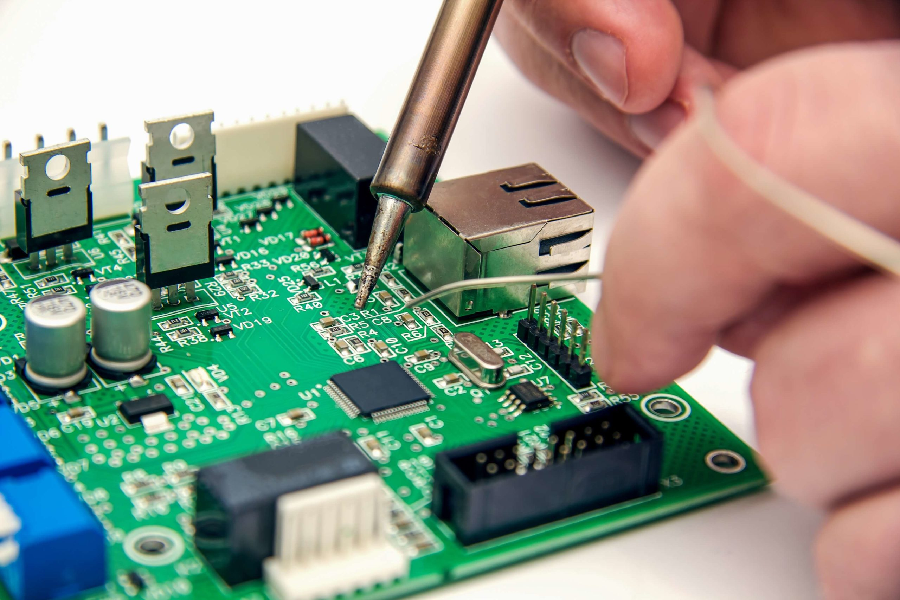

Automated optical inspection (AOI) is an automated method of inspection of a printed circuit board. This method of inspection has also been referred to as a visual inspection. In this method, a camera scans the device that is under test for the presence of quality defects (components skew, defects in shape and sizes) and catastrophic failures (missing components). This method is used to inspect printed circuit boards (PCB).

This method is used to perform checks during the manufacturing process because this is a non-contact test method and is implemented during other stages of the manufacturing process like

- Bare board inspection

- Pre-reflow

- Post free flow

- Solder paste inspection et cetera

If you are thinking of getting AOI done for your product, check out automated optical inspection system Malaysia. This is a company that is dedicated to bringing the best manufacturing test solutions, liquidating the unused excess as well as ensuring ROI in purchases. They have a worldwide supply chain and customer support.

Why is AOI important?

When you are designing a PCB, assuming that you have made the correct design, if you put the right parts at the right designated places, the product should work.

AOI acts as a vital inspection system here. It enables a manufacturer to monitor and measure the quality of PCB production. It also allows the manufacturer to correct any defects or issues at any point in the workflow. AOI can be seen as a quality gate for your PCB manufacturing process. PCB is the brain of the product. Therefore, it has its own precise design requirements. In case of defects, they can get picked up by the AOI.

Role of AOI

The AOI works by using multiple strategies to analyze whether the PCB has been produced as per required standards. By constantly analyzing the faulty data, your EMS partner can make sure that the issues are getting identified at the right time. This will enable you to make improvements in your manufacturing process, minimizing any future risk of rework and increasing your production efficiency as well.

What type of defect will the AOI detect?

There are many defects detected by AOI. A few commonly known defects in PCB assembly that get detected are:

- Incorrect, missing, and skewed components

- Open circuit, shorts, and thinning of the solder

- Scratches, nodules, and stains

- Line width violations

- Excessive copper and missing pad

With the advent of more handheld devices, it is becoming easier to test complex electronic PCBs. Nowadays, digital LCR meters have an electronic and mechanical design combined with tweezers. These are mostly battery-powered. LCR meters are responsible for detecting the capacitance, resistance, or inductance of the PCBs and troubleshoot problems. If you want to buy LCR meters, check out LCR meter Malaysia. The parent company, MTSC solutions, aims to provide the best services to their customers and optimize the manufacturing test solutions. They ensure ROI in your capital equipment purchases as well as help you liquidate the unused excess.